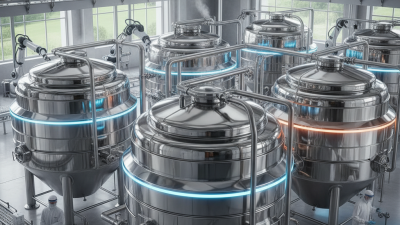

- Blenders, Mixers, & Agitators

- Tri Clamp Mixers

- Top Entry Mixers

- High Viscosity Mixers

- Mag Drive Mixers

- Explosion Proof Mixers

- Sanitary Mixers

- Single Use Mixers & Agitators

- Bottom Entry Mixers

- Carboy Mixers

- Corrosion Resistant Mixers & Mixing Tanks

- Industrial Mixers

- Blenders & Shakers

- Industrial Mixing Accessories

- Sanitary & Industrial Mixing Impellers

- Mixing Tanks & Engineered Systems

- Mechanical Seals

- Applications

2025 Guide: How to Use a 275 Gallon IBC Tote Tank Effectively

In the world of fluid storage and transportation, the 275 gallon ibc tote tank has emerged as a versatile solution for various industries, from agriculture to construction and beyond. Experts in the field, such as John Smith, a renowned authority on industrial storage solutions, emphasize the importance of maximizing the potential of these tanks. "When used effectively, a 275 gallon ibc tote tank can enhance operational efficiency and minimize waste," he notes, underscoring the value these tanks bring to their users.

This guide aims to provide practical insights and helpful tips on how to harness the full capabilities of the 275 gallon ibc tote tank. From understanding its design and features to exploring innovative applications, we will delve into the best practices that ensure safe and effective usage. Additionally, we will discuss maintenance strategies that prolong the life of your tank and optimize your storage solutions.

As we explore these topics, our goal is to empower users with the knowledge they need to leverage the advantages of the 275 gallon ibc tote tank, ensuring that they not only meet their storage needs but also contribute positively to their operations and the environment.

Understanding the 275 Gallon IBC Tote Tank: Specifications and Uses

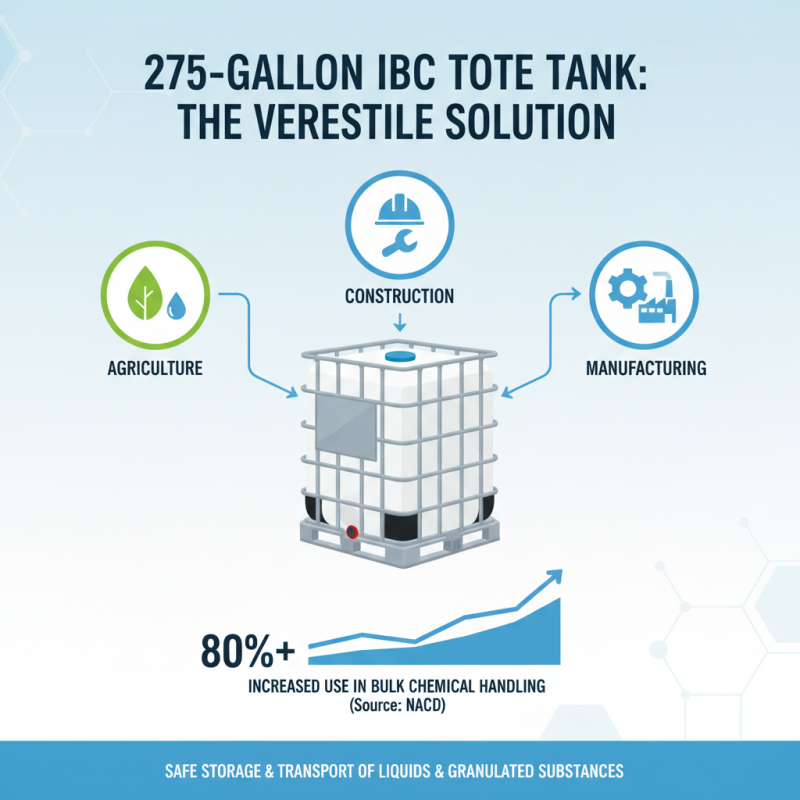

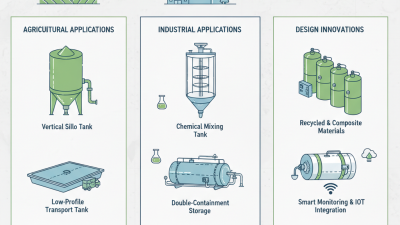

The 275-gallon Intermediate Bulk Container (IBC) tote tank is a versatile solution widely used across various industries, including agriculture, construction, and manufacturing. This container, typically made from durable polyethylene, is designed for the safe storage and transport of liquids and granulated substances. According to the National Association of Chemical Distributors (NACD), the use of IBC totes has increased significantly, with more than 80% of companies now utilizing these containers, particularly for bulk chemical handling.

One of the key specifications of the 275-gallon IBC tote is its impressive capacity, allowing businesses to efficiently manage large volumes of liquids while minimizing storage space. This makes it an ideal choice for operations that require frequent transport of liquids, such as fertilizers or industrial chemicals. The container's design includes a robust steel frame that provides added protection against damage during transport. Moreover, its compatibility with standard forklift handling systems enhances its functionality in warehouse and logistics applications, as noted in a 2022 report by the Global Bulk Container Market Research.

Moreover, the versatility of the 275-gallon IBC tote extends beyond its capacity and structural integrity; it offers various applications, including water storage, chemical mixing, and even as temporary containment for wastewater. The ability to easily stack these totes and their reusability for different substances further adds to their appeal, aligning with sustainability trends observed across industries. According to recent data from the International Council on Clean Transportation, implementing bulk containers like IBC totes can lead to a significant reduction in the carbon footprint associated with packaging waste and transportation operations.

Selecting the Right Materials for Your IBC Tote: A Comprehensive Guide

When selecting the right materials for your 275-gallon IBC tote tank, it's crucial to consider the type of liquids you plan to store and transport. IBC totes are available in various materials, such as polyethylene and stainless steel, each catering to specific storage needs. Polyethylene is a popular choice due to its lightweight, durable, and corrosion-resistant properties, making it ideal for chemicals and non-hazardous liquids. On the other hand, stainless steel totes offer enhanced strength and longevity, suitable for more demanding environments and hazardous materials.

Another vital aspect is understanding the compatibility of the tote material with the stored product. For instance, if you are dealing with aggressive chemicals, it's essential to verify that the tote's construction can withstand potential reactions. Additionally, the tote's UV resistance and temperature endurance should be evaluated to ensure the integrity of the contents over time. Conducting thorough research on the specifications of each material ensures that your IBC tote effectively meets your operational requirements while keeping your materials safe.

Best Practices for Filling and Using IBC Totes Safely and Efficiently

When utilizing a 275-gallon IBC tote tank, ensuring safety and efficiency in both filling and usage is paramount. According to a report by the Environmental Protection Agency (EPA), proper handling and storage of large liquid containers can significantly reduce the risk of spills and contamination. One of the best practices is to always inspect the tote for any signs of damage or corrosion before filling. This helps prevent unforeseen leaks, which are not only a safety hazard but can also lead to costly clean-up operations.

Furthermore, it is recommended to fill the IBC tote at a slow and steady rate. A study published in the Journal of Hazardous Materials indicates that overfilling can cause hazardous substances to overflow, leading to environmental and safety incidents. To optimize usage, users should also consider the tote's material compatibility with the liquids being stored, ensuring that the tote does not degrade over time. Adhering to these guidelines can enhance the longevity of the tote while maintaining compliance with safety regulations, ultimately leading to a more effective and responsible storage solution.

Maintenance Tips for Extending the Lifespan of IBC Tote Tanks

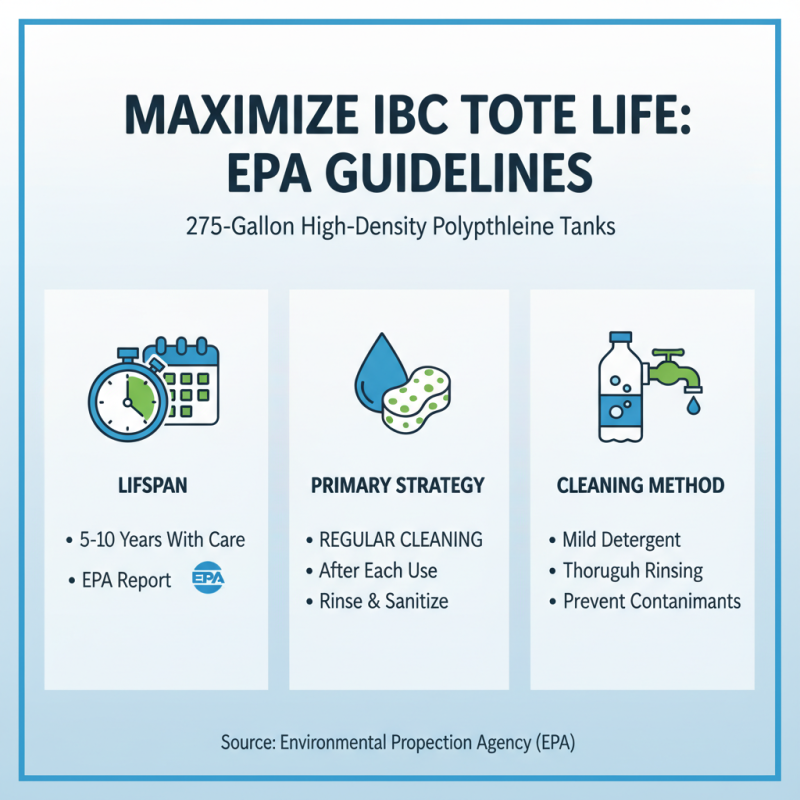

Proper maintenance of 275-gallon IBC tote tanks is crucial for extending their lifespan and ensuring safe and effective use. According to a report by the Environmental Protection Agency (EPA), IBC totes, typically made from high-density polyethylene, can last anywhere from 5 to 10 years with proper care. One of the primary maintenance strategies is regular cleaning. Contaminants can weaken the tank's structure and affect its contents, so it’s advisable to rinse and sanitize the tank after each use. Utilizing a mild detergent and ensuring thorough rinsing prevents any residual chemicals from compromising future applications.

Additionally, storage conditions play a significant role in the longevity of IBC tote tanks. The Packaging Waste Recovery note states that exposure to extreme temperatures and UV light can degrade the material over time. Thus, it’s recommended to position IBC totes in shaded, temperature-controlled environments when not in use. Using protective covers or UV-resistant tarps can further minimize exposure to harmful elements. By implementing these straightforward maintenance practices, users can maximize the functionality and lifespan of their IBC tote tanks, ultimately leading to reduced costs and less environmental impact over time.

Environmental Impact of IBC Tote Usage and Disposal Procedures

The use of intermediate bulk containers (IBCs), particularly 275-gallon tote tanks, has garnered increasing attention due to their efficiency in storing and transporting liquids. However, the environmental impact of their usage and disposal must be carefully considered. IBC totes are predominantly made from recyclable materials, which can significantly reduce waste if properly managed. When utilized effectively, these tanks can minimize spillage and leakage, decreasing the risk of soil and water contamination. Proper storage practices and regular maintenance prolong their lifespan, ultimately leading to a smaller carbon footprint associated with their production and disposal.

Disposal procedures for IBC totes are crucial in mitigating environmental damage. It is essential for users to follow local regulations regarding the disposal of these containers, as improper disposal can lead to hazardous waste issues. Many communities offer recycling programs specifically designed for IBCs, ensuring that the materials are processed safely and reused. Users can also consider repurposing totes for non-hazardous applications, contributing to a circular economy. By understanding the full lifecycle of an IBC tote, from effective usage to responsible disposal, individuals can make choices that promote sustainability and reduce their ecological impact.

2025 Guide: How to Use a 275 Gallon IBC Tote Tank Effectively

| Dimension | Value |

|---|---|

| Volume Capacity | 275 Gallons |

| Dimensions (L x W x H) | 48" x 40" x 46" |

| Weight (Empty) | 120 lbs |

| Material | High-Density Polyethylene (HDPE) |

| Recycling Code | #2 HDPE |

| Average Lifespan | 5-7 years |

| Common Uses | Liquid storage, water collection, agricultural chemicals |

| Environmental Impact Rating | Low when recycled properly |

| Disposal Procedure | Triple rinse, recycle or dispose at designated facilities |

Related Posts

-

2025 Top 10 Uses for 275 Gallon IBC Tote Tanks You Need to Know

-

How to Choose the Right IBC Storage Tank for Your Needs

-

2025 Top PE Tank Designs: What You Need to Know for Your Projects

-

Top 10 Best Water Supply Tanks for Reliable Water Storage Solutions

-

10 Best Chemical Mixing Tanks for Optimal Performance in 2023

-

Why Jacketed Stainless Steel Tanks Are Essential for Food Processing Operations