- Blenders, Mixers, & Agitators

- Tri Clamp Mixers

- Top Entry Mixers

- High Viscosity Mixers

- Mag Drive Mixers

- Explosion Proof Mixers

- Sanitary Mixers

- Single Use Mixers & Agitators

- Bottom Entry Mixers

- Carboy Mixers

- Corrosion Resistant Mixers & Mixing Tanks

- Industrial Mixers

- Blenders & Shakers

- Industrial Mixing Accessories

- Sanitary & Industrial Mixing Impellers

- Mixing Tanks & Engineered Systems

- Mechanical Seals

- Applications

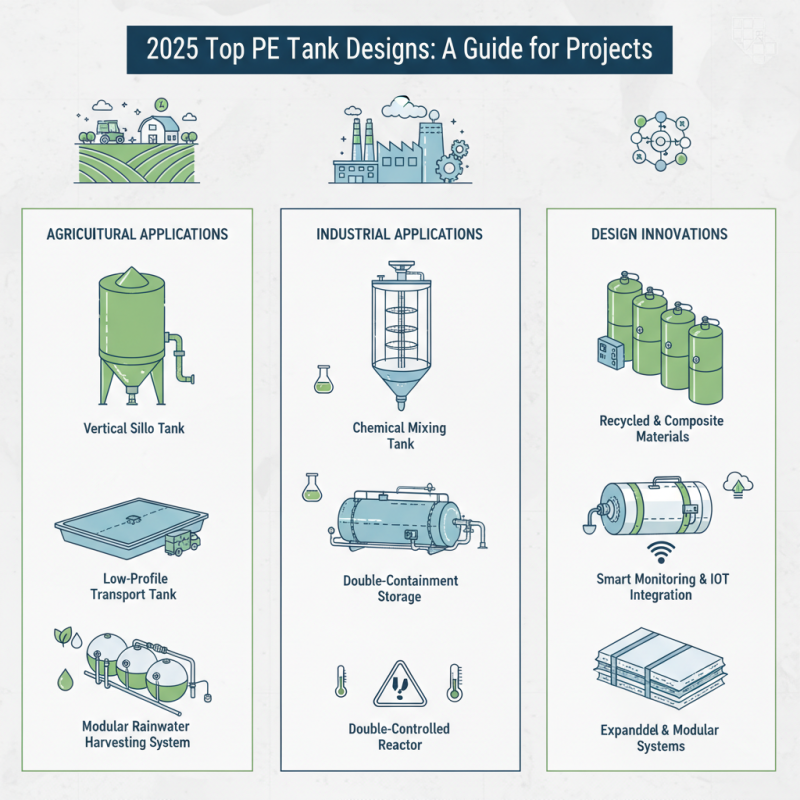

2025 Top PE Tank Designs: What You Need to Know for Your Projects

When it comes to modern storage solutions, PE tanks have emerged as a popular choice for a variety of applications, from agricultural to industrial sectors. In 2025, the demand for innovative and efficient PE tank designs is anticipated to increase significantly, driven by the need for reliable and environmentally friendly storage options. Understanding the key aspects of PE tank design will not only help you make informed decisions for your projects but also ensure compliance with safety standards and operational efficiency.

The primary focus of this article is to explore the top PE tank designs available in 2025, offering insights into their features, advantages, and suitability for different applications. By analyzing the latest technological advancements and trends, we aim to provide a comprehensive guide that will equip you with the knowledge necessary to select the right PE tank for your specific needs. Whether you're planning a large-scale industrial facility or a small agricultural setup, understanding the fundamentals of PE tank design will ultimately enhance your project's success and sustainability.

Understanding PE Tanks: Definition and Applications

Polyethylene (PE) tanks are essential components in various industries, valued for their durability and versatility. These tanks are made from high-density polyethylene, offering resistance to corrosion, chemicals, and UV exposure. As a result, PE tanks are widely used in water storage, agricultural applications, and wastewater treatment. Their lightweight nature makes installation easier, while their seamless construction ensures leak-proof performance, making them an ideal choice for both residential and commercial projects.

When selecting a PE tank for your project, it's crucial to consider factors like size, capacity, and intended use. Different configurations are available to meet various needs, whether for rainwater harvesting or chemical storage. Additionally, be aware of local regulations regarding tank installation and safety standards, which can vary by region.

Tips: Always consult with suppliers to verify the specifications of the tanks you intend to use, ensuring they meet your project’s requirements. Furthermore, regular maintenance is key; clean and inspect your PE tank periodically to prevent buildup of impurities and ensure longevity. Finally, consider implementing protective measures, such as shading the tank from direct sunlight, to prolong its lifespan and maintain water quality.

Key Features of 2025 Top PE Tank Designs

When considering the evolving landscape of polyethylene (PE) tank designs for 2025, several key features stand out that can significantly enhance project efficiency and sustainability. One of the most notable trends is the shift towards lightweight materials that not only ensure durability but also ease transportation and installation. According to a recent industry report, 80% of leading manufacturers are adopting advanced polymer technology, resulting in tanks that are both robust and less taxing on resources. This shift maximizes the longevity of installations, reducing maintenance costs and improving ROI for various applications.

Another critical factor to consider is the integration of smart technology. Modern PE tank designs increasingly feature monitoring systems that provide real-time data on liquid levels, temperature, and other vital parameters. A study by the Water Environment Federation indicates that facilities utilizing such smart tanks report a 30% increase in operational efficiency. By enabling proactive management and reducing the risk of overflow or contamination, these innovations are essential for anyone looking to enhance their project’s reliability.

**Tips:** When selecting a design for your PE tanks, prioritize models that incorporate UV stabilization to improve lifespan and maintain structural integrity. Additionally, consider tanks with modular designs, allowing for easy expansion or modification based on future needs. These strategic choices can greatly optimize project outcomes and align with modern sustainability goals.

Material Characteristics and Benefits of Polyethylene

Polyethylene (PE) has become a material of choice in various tank designs, primarily due to its exceptional characteristics. One of the standout features of polyethylene is its remarkable resistance to corrosion. Unlike metal tanks, PE tanks do not succumb to rust or other chemical degradations, making them ideal for storing a wide range of substances, including water, chemicals, and food products. This inherent durability allows for a longer lifespan, which is crucial for projects requiring reliable and maintenance-free storage solutions.

Another significant benefit of polyethylene is its lightweight nature combined with high strength. This balance allows for easier handling and installation, reducing labor costs and time in project execution. Additionally, PE tanks can be fabricated in various shapes and sizes, providing versatility to meet specific project needs. Their ability to withstand extreme temperatures also makes them suitable for diverse environmental conditions. With these material characteristics, polyethylene not only improves project efficiency but also enhances the overall safety and functionality of tank storage solutions.

Design Considerations for Optimal Performance in Projects

When designing polyethene (PE) tanks for various projects, several key considerations can significantly enhance their performance and longevity. First and foremost, the tank's intended use should dictate its size and shape. Whether for agricultural, industrial, or residential applications, understanding storage requirements and environmental conditions is crucial. For example, tanks exposed to extreme temperatures may require insulative coatings or specific materials that can withstand such conditions, thereby ensuring the stored contents remain stable.

Additionally, the structural integrity of PE tanks is influenced by factors such as wall thickness and reinforcements. Thicker walls can enhance resistance to pressure and impacts, especially in applications involving liquids with varying densities. Furthermore, incorporating design features such as baffles can reduce sloshing and improve stability during transport. Adequate venting systems should also be designed to prevent vacuum formation and ensure smooth fluid flow. By paying careful attention to these design considerations, project managers can ensure optimal performance, safety, and durability of their PE tank systems.

2025 Top PE Tank Designs: What You Need to Know for Your Projects

| Design Feature | Importance | Common Application | Material Type | Capacity Range (liters) |

|---|---|---|---|---|

| UV Resistance | Prevents degradation from sunlight | Water storage | Polyethylene | 500 - 5000 |

| Corrosion Resistance | Increases lifespan of the tank | Chemical storage | HDPE | 1000 - 10000 |

| Flexibility | Allows for expansion and contraction | Liquid transport | LLDPE | 200 - 2000 |

| Weight | Eases transportation and installation | On-site construction | Recycled polyethylene | 300 - 3000 |

| Insulation | Maintains temperature of contents | Heating systems | Foamed polyethylene | 100 - 10000 |

Future Trends in PE Tank Technology and Design Innovations

As we look ahead to 2025, the landscape of polyethylene (PE) tank technology is evolving rapidly, driven by innovation and sustainability demands. One major trend is the integration of advanced materials that enhance durability while minimizing environmental impact. These new materials not only increase the lifespan of PE tanks but also offer superior protection against corrosion and environmental stressors. This enhances their utility in various applications, from agricultural to industrial uses, ensuring they remain functional and cost-effective over time.

Another significant trend is the adoption of smart technologies within PE tank designs. The implementation of sensors and IoT devices allows for real-time monitoring of tank conditions, such as fluid levels and structural integrity. This data-driven approach enables proactive maintenance, reducing downtime and improving operational efficiency. Such innovations are expected to play a critical role in optimizing resource management, making PE tanks not just storage solutions but integral components of smart infrastructure in the coming years.

Related Posts

-

Top 5 Benefits of Using PE Tanks for Water Storage Solutions

-

2025 Top 10 Uses for 275 Gallon IBC Tote Tanks You Need to Know

-

How to Choose the Right IBC Storage Tank for Your Needs

-

Top 10 Best Water Supply Tanks for Reliable Water Storage Solutions

-

Why Jacketed Stainless Steel Tanks Are Essential for Food Processing Operations