- Blenders, Mixers, & Agitators

- Tri Clamp Mixers

- Top Entry Mixers

- High Viscosity Mixers

- Mag Drive Mixers

- Explosion Proof Mixers

- Sanitary Mixers

- Single Use Mixers & Agitators

- Bottom Entry Mixers

- Carboy Mixers

- Corrosion Resistant Mixers & Mixing Tanks

- Industrial Mixers

- Blenders & Shakers

- Industrial Mixing Accessories

- Sanitary & Industrial Mixing Impellers

- Mixing Tanks & Engineered Systems

- Mechanical Seals

- Applications

2025 Top PE Tank Features Benefits and Uses for Your Projects

As the demand for efficient and reliable storage solutions grows across various industries, the significance of Polyethylene (PE) tanks has become increasingly evident. Renowned PE tank expert, Dr. Mark Thompson, notes, "Incorporating high-quality PE tanks in your projects not only enhances durability but also significantly reduces maintenance costs." This statement encapsulates the essence of why PE tanks are a vital component in project planning and execution.

PE tanks are not only versatile but also offer numerous benefits that cater to a range of applications from agriculture to industrial uses. Their lightweight construction, resistance to corrosion, and excellent chemical compatibility make them an ideal choice for safe storage of liquids. In this article, we will explore the top features of PE tanks for 2025, highlighting their benefits and various applications to help you make informed decisions for your upcoming projects.

Understanding these characteristics is crucial for both engineers and project managers aiming for efficiency and sustainability. With innovations in design and technology, the future of PE tank applications looks promising. This is a pivotal moment to delve into how these tanks can be integrated into your projects to maximize performance and cost-effectiveness.

Key Features of PE Tanks for Modern Applications

When evaluating PE tanks for modern applications, several key features stand out that make them indispensable for various projects. One of the primary benefits of PE tanks is their high durability and resistance to environmental factors such as UV rays, corrosion, and extreme temperatures. This resilience ensures a longer lifespan and reduced maintenance costs, making them a smart investment for industries ranging from agriculture to chemical processing.

Tips: When selecting a PE tank for your project, consider factors such as the specific chemicals or substances it will hold, as well as the local climate conditions. Ensuring the tank is adequately sized for your needs can also optimize efficiency and performance.

Another feature worth noting is the lightweight nature of PE tanks, which facilitates easier installation and transport. Their flexible design allows for a variety of shapes and sizes, accommodating unique project requirements. This adaptability makes PE tanks a preferred choice for both permanent installations and temporary setups across different sectors.

Tips: Always verify the specifications provided by manufacturers to ensure that the tank meets your specific application needs. Proper installation techniques can also enhance the tank's performance and longevity, so it’s advisable to consult with professionals if you're unsure.

2025 Top PE Tank Features Benefits and Uses for Your Projects

Understanding the Benefits of Polyethylene Tanks in Various Industries

Polyethylene (PE) tanks have become essential components in various industries due to their durability, versatility, and cost-effectiveness. These tanks are primarily utilized for storing liquids, including water, chemicals, and agricultural products. One of the significant advantages of polyethylene tanks is their resistance to corrosion and rust, which makes them suitable for environments that may be harsh on traditional metal tanks. Their lightweight nature allows for easier installation and transportation, reducing labor costs and facilitating smoother operations.

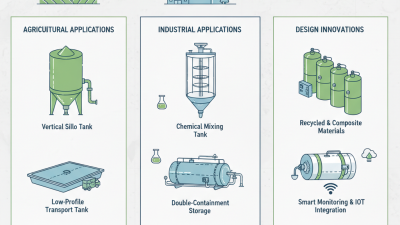

In addition to their physical benefits, PE tanks are also known for their adaptability across different applications. In the agricultural sector, they are commonly used for irrigation and fertilizer storage, ensuring that farmers can efficiently manage their resources. The chemical industry benefits from polyethylene's ability to store a wide range of chemicals safely, as it does not react with most substances. Furthermore, the ability to manufacture these tanks in various sizes and shapes enables industries to customize storage solutions that best fit their specific operational needs, thereby optimizing efficiency and workflow.

Common Uses of PE Tanks in Water Storage and Treatment Solutions

PE tanks, composed of high-density polyethylene, have gained popularity in various water storage and treatment applications due to their durability and efficiency. These tanks are commonly used in agricultural settings where they provide a reliable source for irrigation, ensuring that crops receive consistent water supply without the risk of contamination. Their lightweight design makes installation simple and cost-effective, allowing for easy transport and positioning on-site.

In industrial contexts, PE tanks are employed to hold and transport chemicals and wastewater. Their resistance to a broad range of chemicals minimizes the risk of leakage, making them a preferred choice for treatment facilities. Additionally, these tanks are frequently utilized in residential settings for rainwater harvesting systems, allowing homeowners to collect and store rainwater for later use in gardening or other non-potable applications. The versatility of PE tanks positions them as an essential component in modern water management strategies. Their ability to withstand extreme weather conditions without degrading further enhances their appeal for both commercial and residential projects.

2025 Top PE Tank Features Benefits and Uses for Your Projects

| Feature | Benefit | Common Uses |

|---|---|---|

| Durability | Resistant to corrosion and impact | Industrial water storage |

| Lightweight | Easier to transport and install | Residential rainwater harvesting |

| UV Resistance | Prevents degradation from sunlight | Outdoor water storage |

| Customizable Sizes | Variety of applications | Agricultural water management |

| Chemical Resistance | Safe storage of various liquids | Chemical processing plants |

| Low Maintenance | Reduced long-term costs | Municipal water supply systems |

Comparative Analysis of PE Tanks vs. Other Storage Options

When evaluating storage solutions for various projects, polyethylene (PE) tanks offer distinct advantages over traditional options such as fiberglass and steel tanks. According to a recent industry report, PE tanks boast a corrosion resistance rate exceeding 90%, which significantly extends their lifespan compared to steel tanks that can succumb to rust and degradation in harsh environments. This durability not only ensures long-term performance but also translates into cost savings over time, as users face reduced maintenance and replacement costs.

Furthermore, PE tanks are lightweight and easy to install, with many models featuring modular designs that simplify transport and assembly. Industry data indicates that the installation time for PE tanks can be up to 50% less than that required for conventional materials, allowing for more efficient project timelines. Additionally, their chemical resistance properties make PE tanks suitable for a wider range of applications, including the storage of agricultural chemicals, potable water, and waste, which cannot be standardized in other materials. This versatility aligns with the growing trend in sustainable practices, as the adaptability of PE tanks supports the diverse needs of modern projects without compromising on safety or environmental considerations.

Innovative Design Trends in PE Tanks for Enhanced Performance

The innovative design trends in polyethylene (PE) tanks are revolutionizing their performance across various applications. These advancements focus on enhancing durability, efficiency, and environmental sustainability. One key trend is the integration of advanced manufacturing techniques that refine the structural integrity of PE tanks. This results in tanks that are not only lightweight and easy to transport but also capable of withstanding harsh conditions, such as extreme temperatures and chemicals. Additionally, the use of multi-layered designs provides superior protection against UV radiation, prolonging the lifespan of the tanks and reducing the need for frequent replacements.

Moreover, the move towards smart technology integration is shaping the future of PE tanks. Incorporating sensors and monitoring systems allows for real-time data collection, which significantly improves management and operational efficiency. These smart tanks can alert users to changes in liquid levels, detect leaks, and provide insights into usage patterns, which ultimately aids in better resource management. As industries increasingly prioritize sustainability, these design trends underscore the importance of PE tanks that not only meet current demands but also embrace the evolving landscape of eco-friendly practices. Emphasizing flexibility in size and design further enables customized solutions tailored to specific project needs, reinforcing their utility in a wide range of applications.

Related Posts

-

2025 Top 10 Uses for 275 Gallon IBC Tote Tanks You Need to Know

-

Top 5 Benefits of Using PE Tanks for Water Storage Solutions

-

How to Choose the Right IBC Storage Tank for Your Needs

-

Why Jacketed Stainless Steel Tanks Are Essential for Food Processing Operations

-

Top 10 Best Water Supply Tanks for Reliable Water Storage Solutions

-

2025 Top PE Tank Designs: What You Need to Know for Your Projects