- Blenders, Mixers, & Agitators

- Tri Clamp Mixers

- Top Entry Mixers

- High Viscosity Mixers

- Mag Drive Mixers

- Explosion Proof Mixers

- Sanitary Mixers

- Single Use Mixers & Agitators

- Bottom Entry Mixers

- Carboy Mixers

- Corrosion Resistant Mixers & Mixing Tanks

- Industrial Mixers

- Blenders & Shakers

- Industrial Mixing Accessories

- Sanitary & Industrial Mixing Impellers

- Mixing Tanks & Engineered Systems

- Mechanical Seals

- Applications

Top Advantages of Using a Heated Mixing Tank in Industrial Processes?

In the industrial landscape, the role of a heated mixing tank is pivotal. According to Dr. Jane Smith, a leading expert in chemical engineering, “A heated mixing tank can significantly enhance reaction efficiency.” This highlights the importance of temperature control in mixing processes.

Heated mixing tanks provide consistent heat distribution, which is essential for certain applications. Industries, such as food production and pharmaceuticals, often rely on precise temperature management. However, not all companies maximize this benefit. Some still use traditional methods that are less efficient.

Additionally, the operational costs can impact decisions about heated mixing tanks. Investing in quality mixers sometimes feels overwhelming. While these systems can improve productivity, some businesses hesitate to fully embrace them. The pathway to greater efficiency might be clear, but the journey contains uncertainties.

Key Benefits of Heated Mixing Tanks in Industrial Applications

Heated mixing tanks are crucial in many industrial processes. They help achieve the right temperature for optimal mixing. Temperature control can enhance the solubility of certain materials. This leads to a more homogeneous mixture. Additionally, better mixing can reduce processing times significantly.

Using heated mixing tanks also improves product quality. When ingredients are mixed at the right temperature, reactions occur more effectively. This can lead to higher yield and fewer defects in the final product. However, one must monitor temperature carefully. Overheating can cause unwanted reactions, or alter the composition.

Moreover, these tanks can be energy-intensive. It's important to evaluate energy efficiency regularly. Organizations need to balance operational costs with benefits. In some cases, not investing in the latest technology may seem practical. Reflecting on these choices will lead to better long-term strategies.

Enhanced Material Consistency Through Uniform Heating

Heated mixing tanks are revolutionizing industrial processes. They ensure uniform heating, which is vital for achieving enhanced material consistency. Studies show that inconsistent heating can lead to variations in product quality. A report by the National Institute of Standards and Technology highlights that temperature variations can cause up to a 25% difference in material properties.

Uniform heating promotes even blending of ingredients. This can reduce batch processing times significantly. When materials are consistently heated, reaction times improve. In some cases, this can cut processing time by 30%. It leads to more reliable end products. Many industries, from food to chemicals, have embraced this technology for its benefits.

Tip: Regularly calibrate your heating system to maintain efficiency. Even minor discrepancies can impact outcomes. Another tip is to analyze material loading patterns. This can help ensure that heating is effective throughout the tank. Remember, achieving perfect consistency takes continuous refinement. Experiment with settings to find the optimal solution for your specific materials.

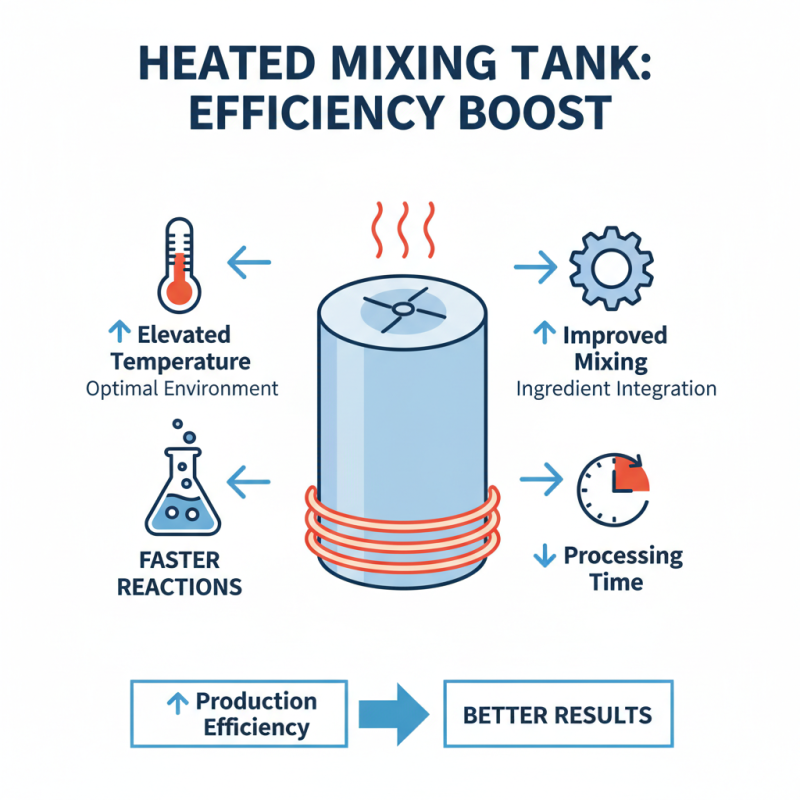

Improved Reaction Rates for Enhanced Production Efficiency

A heated mixing tank significantly boosts reaction rates in various industrial processes. By maintaining elevated temperatures, these tanks create an optimal environment for chemical reactions. This leads to faster mixing and better ingredient integration. The result? Improved production efficiency and reduced processing time.

Many industries benefit from these tanks. In pharmaceuticals, precise temperature control enhances drug formulation. Similarly, in food production, heated tanks ensure uniform cooking and flavor development. Each of these processes demands specific temperature settings for effective reactions. However, achieving the perfect balance can be challenging. Too much heat can degrade sensitive components.

In practice, constant monitoring is crucial. Operators must ensure that the temperature remains stable throughout the mixing process. Any deviation can lead to undesirable outcomes. This demands skill and attention to detail. Beyond efficiency, the use of heated mixing tanks highlights the importance of temperature management in production. Striving for the right conditions remains a continual learning process for many industries.

Reduction of Energy Consumption and Operational Costs

The adoption of heated mixing tanks in industrial processes offers substantial advantages, particularly in energy consumption and operational costs. Recent studies indicate that efficient mixing systems can reduce energy usage by up to 30%. This reduction not only translates to lower utility bills but also lessens the carbon footprint of manufacturing facilities. Moreover, less energy spent means improved overall productivity, allowing companies to allocate resources more effectively.

In many cases, heated mixing tanks can maintain optimal temperature ranges with greater consistency. This stability ensures better product quality and less waste, as materials react more predictably. For instance, when temperature fluctuations occur, chemical reactions can become erratic. This situation often leads to increased rework or scrapping, which impacts both costs and resource management.

Additionally, an optimized heating process typically requires less maintenance. Equipment longevity is crucial, and minimizing downtime for repairs can significantly enhance profitability.

While these benefits are significant, companies must also reflect on their initial investment. The upfront costs for installing a heated mixing tank can be considerable. However, when viewed through the lens of long-term savings, many enterprises find the investment worthwhile. Balancing these costs and benefits requires a careful examination of each facility’s specific needs. Clear analysis ensures that the switch to heated mixing technologies is economically viable and aligns with sustainability goals.

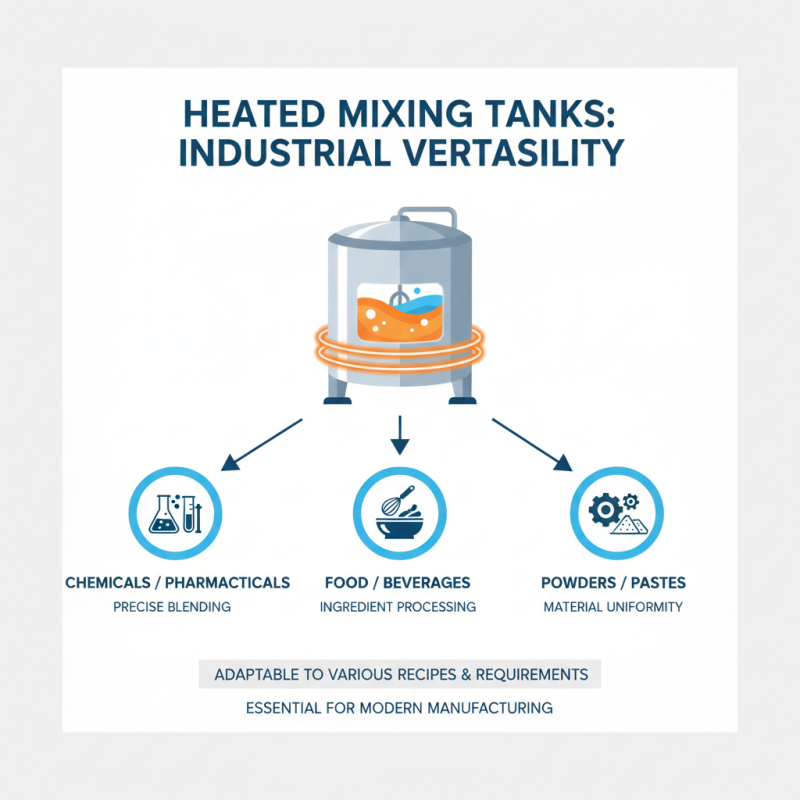

Versatility in Processing Different Types of Materials

Heated mixing tanks are essential in many industrial processes, offering immense versatility. They can effectively process a variety of materials, such as liquids, powders, and pastes. This flexibility allows manufacturers to adapt quickly to changing requirements. Whether blending chemicals, food ingredients, or pharmaceuticals, heated tanks can accommodate different recipes.

Temperature control plays a crucial role in the mixing process. It enables even mixing and helps dissolve solids faster. However, some operators may struggle with maintaining precise temperatures. Inconsistent heating can lead to uneven mixtures and inferior product quality. Training and regular maintenance are vital to address these issues.

The design of heated mixing tanks also enhances their functionality. Many models feature adjustable agitation speeds and specialized mixing blades. This adaptability can improve performance, but not every tank is perfect for all tasks. Sometimes, trial and error may be necessary to identify the best setups. Overall, the versatility of heated mixing tanks makes them invaluable in multiple industrial applications, even if some challenges remain.

Conclusion

Heated mixing tanks offer significant advantages in industrial processes, proving to be essential tools for enhancing production efficiency. One of the primary benefits is the enhanced material consistency achieved through uniform heating, which ensures that the components are thoroughly mixed and react uniformly. This uniformity not only streamlines production but also improves reaction rates, allowing for quicker turnaround times in manufacturing.

Moreover, heated mixing tanks contribute to energy efficiency by reducing overall energy consumption and operational costs. Their versatility allows for the processing of various material types, making them invaluable across multiple industries. Additionally, these tanks facilitate complex mixing processes, enabling more sophisticated production techniques. Overall, the adoption of heated mixing tanks can lead to a more efficient and cost-effective industrial operation, demonstrating their critical role in modern manufacturing.

Related Posts

-

2025 Top PE Tank Features Benefits and Uses for Your Projects

-

Top Open Top Tank Options for 2025 Essential Considerations and Features

-

2025 Guide: How to Use a 275 Gallon IBC Tote Tank Effectively

-

2025 Top 10 Uses for 275 Gallon IBC Tote Tanks You Need to Know

-

How to Use a 275 Gallon IBC Tote Tank Effectively?

-

Why Jacketed Stainless Steel Tanks Are Essential for Food Processing Operations