- Blenders, Mixers, & Agitators

- Tri Clamp Mixers

- Top Entry Mixers

- High Viscosity Mixers

- Mag Drive Mixers

- Explosion Proof Mixers

- Sanitary Mixers

- Single Use Mixers & Agitators

- Bottom Entry Mixers

- Carboy Mixers

- Corrosion Resistant Mixers & Mixing Tanks

- Industrial Mixers

- Blenders & Shakers

- Industrial Mixing Accessories

- Sanitary & Industrial Mixing Impellers

- Mixing Tanks & Engineered Systems

- Mechanical Seals

- Applications

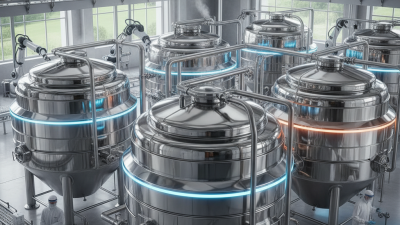

Top 10 Benefits of Using Stainless Tanks in Various Industries

The utilization of stainless tanks in various industries has seen a significant rise due to their remarkable durability, corrosion resistance, and overall efficiency. According to recent reports from the International Stainless Steel Forum, the stainless steel market is projected to grow at a CAGR of approximately 5% over the next five years, driven largely by the increasing demand across sectors such as food and beverage, pharmaceuticals, and chemical processing. The inherent properties of stainless steel, including its ability to withstand high temperatures and maintain hygienic conditions, make stainless tanks an optimal choice for industries that prioritize both safety and reliability.

Furthermore, the global tank market is expected to reach USD 5.1 billion by 2027, with stainless tanks comprising a considerable share due to their long lifespan and low maintenance requirements. The benefits of utilizing stainless tanks extend beyond mere durability; they also promote sustainability by reducing the need for frequent replacements and minimizing waste. As industries continue to evolve and adapt to stringent regulatory standards, the application of stainless tanks stands out as a solution that not only meets high operational standards but also contributes to environmentally responsible practices. In exploring the top ten benefits of using stainless tanks, it becomes evident that they play an integral role in enhancing productivity and ensuring the highest quality of products across various sectors.

Advantages of Corrosion Resistance in Stainless Tanks

Stainless tanks have become a pivotal choice in numerous industries due to their remarkable corrosion resistance. This resilience against corrosive substances is supported by data from recent industry reports, indicating that stainless steel can extend the lifespan of storage and processing equipment by up to 50% compared to other materials. This is especially critical in sectors such as food and beverage, pharmaceuticals, and chemical processing, where even minute amounts of contamination can compromise product integrity and safety.

Moreover, the corrosion resistance of stainless tanks minimizes the need for regular maintenance and replacement, providing significant cost savings over time. According to a report by the American Society of Mechanical Engineers, the total lifecycle cost of stainless steel equipment can be reduced by approximately 30% due to decreased maintenance frequencies and longer operational life. Such benefits not only enhance efficiency but also contribute to a sustainable manufacturing process by reducing waste.

**Tip:** When selecting stainless tanks, consider factors such as the specific grade of stainless steel and the environmental conditions the tanks will face. For example, applications involving highly corrosive chemicals may benefit from specialized grades such as 316 stainless steel, which offers enhanced protection.

**Tip:** Regular inspections can help identify any wear or surface degradation early on, ensuring the tanks maintain their superior performance and longevity. This proactive approach can further leverage the advantages of corrosion resistance inherent in stainless tanks.

Enhanced Durability and Longevity of Stainless Steel Tanks

Stainless steel tanks have become a staple in various industries due to their impressive durability and longevity. The material’s ability to withstand corrosion, rust, and extreme temperatures makes it an ideal choice for storage applications in food, beverage, pharmaceuticals, and wastewater treatment sectors. According to a report by the International Stainless Steel Forum, stainless steel can last significantly longer than carbon steel, with a typical lifespan of over 30 years in harsh environments, ensuring optimal performance and reducing the need for frequent replacements.

One of the main benefits of stainless steel tanks is their inherent resistance to various chemical reactions. For instance, in the food and beverage industries, the use of stainless steel ensures that no flavors or contaminants leach into products, maintaining safety and quality standards. A study by the Food Safety and Inspection Service highlights that stainless surfaces can easily comply with sanitary requirements, further reinforcing their role in promoting longer-lasting, high-quality storage solutions.

Tips: When selecting stainless steel tanks, consider the specific type of stainless steel. For applications involving acidic substances, higher grades such as 316L can provide enhanced corrosion resistance. Regular maintenance, including gentle cleaning and inspection for any signs of wear, can also significantly extend the lifespan of these tanks, thus maximizing their durability. Investing in quality stainless steel tanks will not only improve operational efficiencies but also contribute to long-term cost savings due to decreased maintenance and replacement needs.

Cost-Effectiveness of Stainless Tanks in Industrial Applications

Stainless tanks have become integral in various industrial applications due to their durability and cost-effectiveness. Industries such as food and beverage, pharmaceuticals, and chemical processing utilize stainless tanks for their resistance to corrosion and ability to maintain sanitary conditions. According to a report by the Global Market Insights, the stainless steel tank market is projected to exceed $10 billion by 2026, driven by the increasing demand for high-quality storage solutions. This growth indicates a strong recognition of the economic advantages that stainless tanks offer over alternative materials.

The initial investment in stainless tanks may be higher compared to other materials, but their longevity and low maintenance requirements result in significant long-term savings. A study from the International Journal of Industrial Technology notes that stainless steel tanks can have a lifespan of over 20 years, significantly reducing the need for replacements and repairs. Furthermore, the high resale value of stainless tanks contributes to their cost-effectiveness, making them a wise choice for businesses looking to optimize budgets while ensuring quality.

Tips for Maximizing Cost-Effectiveness with Stainless Tanks:

1. Regular maintenance can extend the lifespan of stainless tanks, reducing overall replacement costs.

2. Investing in high-quality, food-grade stainless steel can help meet regulatory standards and ensure product safety, minimizing potential losses from compliance issues.

3. Consider the size and design of the tank carefully—opt for modular designs that can adapt to future production needs without significant additional investments.

Top 10 Benefits of Using Stainless Tanks in Various Industries

| Benefit | Description | Industry Application | Cost-Effectiveness |

|---|---|---|---|

| Durability | Resistant to corrosion and wear, ensuring a longer lifespan. | Food and Beverage | Lower replacement costs over time. |

| Hygiene | Easy to clean and sanitize, reducing contamination risk. | Pharmaceutical | Minimized product loss and recalls. |

| Versatility | Suitable for a wide range of liquids and materials. | Chemical Manufacturing | Reduces need for multiple tank types. |

| Temperature Resistance | Withstands extreme temperatures without degrading. | Oil and Gas | Enhances energy efficiency in thermal processes. |

| Aesthetic Appeal | Modern and attractive appearance for plant environments. | Brewery | Enhances brand image and consumer trust. |

| Recyclability | 100% recyclable material with no loss of quality. | Waste Management | Lowers material costs for new products. |

| Chemical Resistance | Highly resistant to various chemicals, enhancing safety. | Agriculture | Reduces product degradation and loss. |

| Low Maintenance | Requires minimal upkeep compared to other materials. | Water Treatment | Saves on labor and material costs over time. |

| Temperature Control | Effective in maintaining product temperatures. | Dairy | Improves product quality and reduces waste. |

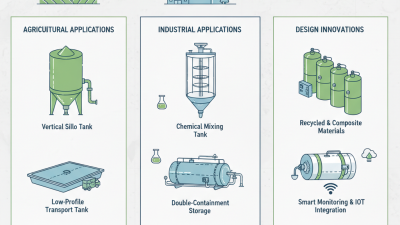

Versatility of Stainless Tanks Across Different Industries

Stainless tanks have become indispensable in various industries due to their versatility and durability. From food processing to pharmaceuticals, these tanks are engineered to withstand a wide range of substances, making them ideal for storing and transporting liquids.

Their resistance to corrosion and staining ensures that products remain uncontaminated, while also extending the life of the tank itself. This versatility not only enhances the safety of operations but also contributes to the efficiency of production processes across different sectors.

Tips for selecting the right stainless tank include considering the specific needs of your industry. For instance, in food and beverage production, choose tanks with smooth surfaces that are easy to clean to adhere to health standards. In chemical processing, ensure that the selected material can handle the specific chemicals involved without degrading or reacting adversely. Regular maintenance is essential for all industries; conducting periodic inspections can prevent costly downtime and ensure the longevity of your stainless tanks.

Additionally, it’s important to account for factors such as tank size and design. Modular tanks offer the flexibility to expand capacity as production demands increase. Understanding the unique requirements of each industry will allow for a more informed decision when investing in stainless tanks, maximizing their benefits and ensuring seamless operations across various applications.

Improved Hygiene Standards with Stainless Tanks in Food Processing

In the food processing industry, maintaining high hygiene standards is paramount, and stainless tanks play a crucial role in achieving this goal. Stainless steel is inherently resistant to corrosion and does not harbor bacteria, making it an ideal material for food storage and processing. The smooth surface of stainless tanks prevents the accumulation of food particles and contaminants, ensuring that products remain uncontaminated throughout their handling and processing phases. This property not only enhances food safety but also extends the shelf life of perishable items, benefiting both producers and consumers.

Furthermore, the ability to easily clean and sanitize stainless tanks adds to their appeal in food processing facilities. Unlike other materials that may require harsh chemicals or extensive scrubbing, stainless steel can be cleaned quickly using standard cleaning agents and methods, promoting efficiency in a fast-paced industry. This ease of maintenance encourages adherence to rigorous hygiene protocols, which is critical given the increasing regulations surrounding food safety. By investing in stainless tanks, food processors can ensure compliance with health standards while also boosting consumer confidence in the safety and quality of their products.

Top 10 Benefits of Using Stainless Tanks in Various Industries

This chart illustrates the top benefits of using stainless tanks across various industries, particularly emphasizing improved hygiene standards in food processing, which is crucial for maintaining product quality and safety.

Related Posts

-

Why Jacketed Stainless Steel Tanks Are Essential for Food Processing Operations

-

10 Best Chemical Mixing Tanks for Optimal Performance in 2023

-

How to Choose the Right Stainless Tank for Your Needs and Applications

-

Top 2025 Guide to Choosing the Best Large Plastic Water Tanks for Your Needs

-

How to Choose the Right IBC Storage Tank for Your Needs

-

2025 Top PE Tank Designs: What You Need to Know for Your Projects