- Blenders, Mixers, & Agitators

- Tri Clamp Mixers

- Top Entry Mixers

- High Viscosity Mixers

- Mag Drive Mixers

- Explosion Proof Mixers

- Sanitary Mixers

- Single Use Mixers & Agitators

- Bottom Entry Mixers

- Carboy Mixers

- Corrosion Resistant Mixers & Mixing Tanks

- Industrial Mixers

- Blenders & Shakers

- Industrial Mixing Accessories

- Sanitary & Industrial Mixing Impellers

- Mixing Tanks & Engineered Systems

- Mechanical Seals

- Applications

10 Best Chemical Mixing Tanks for Optimal Performance in 2023

In the ever-evolving landscape of industrial processes, the significance of a reliable and efficient chemical mixing tank cannot be overstated. As noted by Dr. Emily Carter, a leading expert in chemical engineering, "The design and functionality of a chemical mixing tank are pivotal to achieving optimal performance in any production environment." These tanks are engineered to ensure that various chemical components are blended with precision, leading to enhanced product quality and operational efficiency.

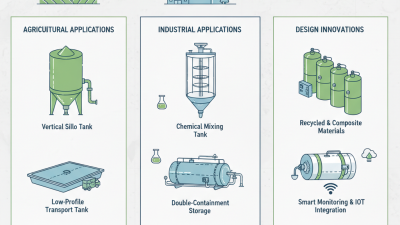

With advancements in technology, the selection of the right chemical mixing tank has become crucial for industries ranging from pharmaceuticals to food processing. Companies are increasingly recognizing that the appropriateness of a mixing tank directly impacts their productivity and safety standards. By evaluating the top choices available in 2023, organizations can better equip themselves to meet their unique operational needs while adhering to regulatory standards.

As we delve into the ten best chemical mixing tanks for optimal performance, it is essential to consider not just the features but also the specific applications that each tank serves. Understanding these elements will empower businesses to make informed decisions that drive both innovation and growth in their respective fields.

10 Key Features to Consider When Selecting Chemical Mixing Tanks

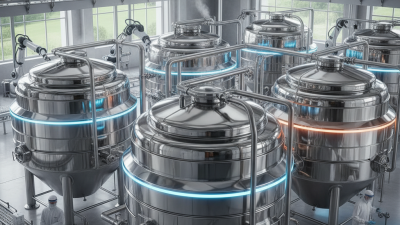

When selecting a chemical mixing tank, several key features play a critical role in ensuring optimal performance. First and foremost is the material of the tank. Depending on the chemicals being mixed, it is essential to choose a tank made from corrosion-resistant materials such as stainless steel or specialized plastic. This not only ensures the longevity of the tank but also maintains the integrity of the chemicals involved. Additionally, the tank's design should facilitate easy cleaning and maintenance, which is crucial for preventing contamination and ensuring safety in environments where hazardous materials are present.

Another vital feature to consider is the tank's capacity and dimensions. The size should be appropriate for the volume of chemicals being processed to avoid overflow or inadequate mixing. Alongside capacity, the mixing mechanism is equally important. Tanks equipped with adjustable agitators provide flexibility in mixing various chemical compositions, enhancing the efficiency of the blending process. Furthermore, features like temperature control and pressure management systems can significantly affect the reactions that take place within the tank, making them critical considerations in the selection process. By focusing on these essential features, operators can ensure they choose a chemical mixing tank that meets their specific needs and enhances overall operational efficiency.

Most Effective Materials Used in Fabricating Chemical Mixing Tanks

When selecting chemical mixing tanks, the materials used in their fabrication play a pivotal role in ensuring optimal performance and longevity. One of the most effective materials employed is high-density polyethylene (HDPE). Known for its excellent chemical resistance, HDPE is ideal for containing a wide range of corrosive substances, making it a desirable choice for various industrial applications. Additionally, its lightweight nature and durability enhance ease of handling, contributing to safer and more efficient operations.

Another widely used material is stainless steel, particularly for applications requiring higher temperature resistance and mechanical strength. Stainless steel tanks not only provide enhanced durability but also offer seamless surfaces that are easier to clean and maintain. This is crucial in industries where cross-contamination is a concern. Furthermore, the non-reactive nature of stainless steel ensures that the integrity of the chemicals remains intact during the mixing process, thereby optimizing performance outcomes.

In some cases, fiberglass-reinforced plastic (FRP) is also an advantageous option. FRP combines the strength of fiberglass with the corrosion resistance of plastics, making it suitable for aggressive chemical environments. Its versatility allows for custom designs that can accommodate unique operational needs while ensuring that the tanks remain lightweight and resistant to various chemical attacks. The choice of material not only impacts the mixing efficiency but also significantly influences the overall safety and reliability of the processes involved.

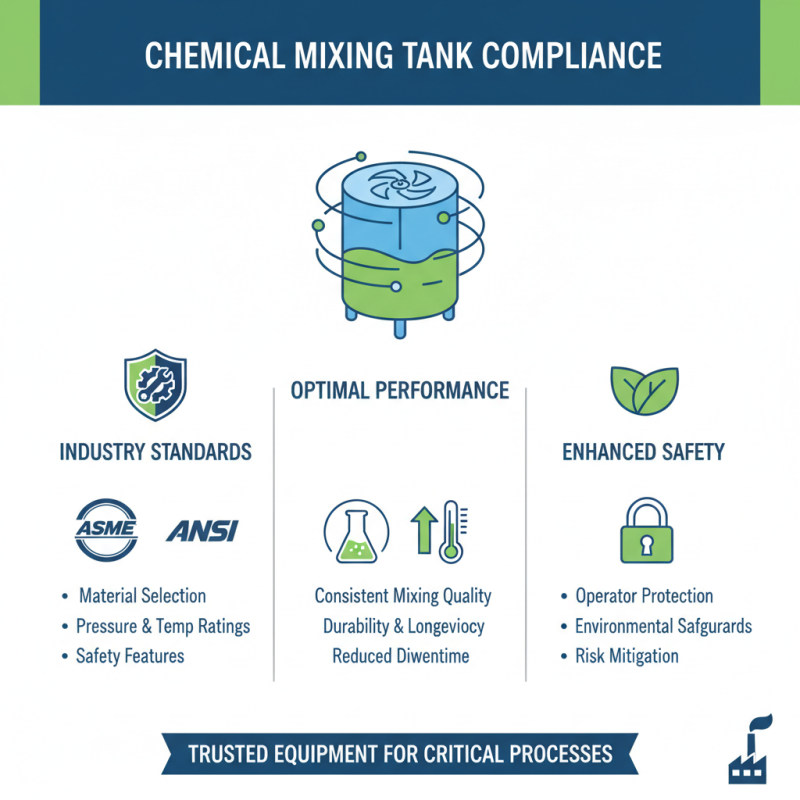

Industry Standards and Certifications for Chemical Mixing Equipment

When selecting a chemical mixing tank, compliance with industry standards and certifications is paramount for ensuring optimal performance and safety. Regulatory organizations such as the American Society of Mechanical Engineers (ASME) and the American National Standards Institute (ANSI) provide guidelines that help manufacturers produce equipment capable of withstanding the rigors of chemical processes. These standards ensure that mixing tanks are constructed from appropriate materials, designed to handle specific pressures and temperatures, and equipped with the necessary safety features to protect operators and the environment.

Moreover, certifications such as ISO 9001 play a crucial role in ensuring that mixing tank manufacturers adhere to quality management practices. This certification not only signifies that a company maintains high standards of production but also assures customers that the equipment is reliable and effective. While selecting a mixing tank, buyers should look for equipment that meets relevant safety and health regulations, such as those outlined by the Occupational Safety and Health Administration (OSHA) and other authoritative bodies. By prioritizing industry standards and certifications, facilities can enhance operational efficiency while minimizing risks associated with chemical mixing processes.

Comparative Analysis of Leading Chemical Mixing Tank Brands in 2023

The realm of chemical mixing tanks has seen significant advancements in technology and design, with various brands vying for supremacy in the market. Each brand offers unique features aimed at enhancing the mixing process, ensuring optimal performance for various chemical compositions. When evaluating these tanks, it is essential to consider factors such as tank material, mixing efficiency, and ease of maintenance. High-quality materials are crucial to withstand corrosive substances while ensuring structural integrity, whereas innovative mixing mechanisms can lead to improved uniformity in the final product.

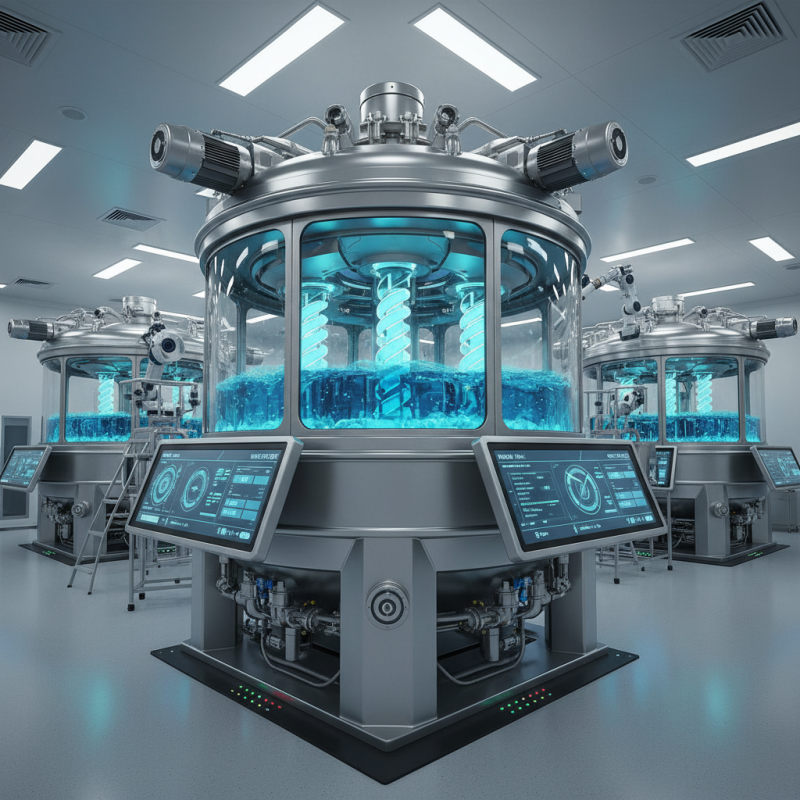

In 2023, the comparative analysis of leading chemical mixing tanks reveals a trend towards more energy-efficient designs and user-friendly controls. Industry professionals are increasingly favoring models that incorporate automation and smart technology, allowing for real-time monitoring and adjustments during the mixing process. This not only enhances performance but also reduces the likelihood of human error. Furthermore, brands that provide comprehensive customer support and maintenance services stand out as more reliable options, emphasizing their commitment to performance and client satisfaction in a competitive market.

Emerging Trends in Chemical Mixing Technology and Their Impact on Performance

Emerging trends in chemical mixing technology are shaping the industry landscape, leading to significant improvements in performance and efficiency. One of the most notable advancements is the integration of smart sensors and IoT devices in mixing tanks. These technologies enable real-time monitoring and data collection, allowing operators to adjust variables such as temperature, viscosity, and mixing speed on-the-fly. As a result, industries can achieve more precise formulations and reduce waste, optimizing the overall chemical mixing process.

Another trend is the growing focus on sustainability and energy efficiency in chemical mixing. Innovative designs are being developed that minimize energy consumption while maximizing output. For instance, the use of advanced impeller designs and variable frequency drives provides greater control over mixing rates, which not only enhances product quality but also lowers operational costs. Additionally, eco-friendly materials are increasingly utilized in the construction of mixing tanks, contributing to a more sustainable manufacturing environment. These developments reflect a broader commitment to resource conservation and reducing the environmental impact of chemical processing.

Related Posts

-

Why Jacketed Stainless Steel Tanks Are Essential for Food Processing Operations

-

Top 10 Best Water Supply Tanks for Reliable Water Storage Solutions

-

2025 Top PE Tank Designs: What You Need to Know for Your Projects

-

Top 5 Benefits of Using PE Tanks for Water Storage Solutions

-

How to Choose the Right IBC Storage Tank for Your Needs

-

2025 Top 10 Uses for 275 Gallon IBC Tote Tanks You Need to Know