- Blenders, Mixers, & Agitators

- Tri Clamp Mixers

- Top Entry Mixers

- High Viscosity Mixers

- Mag Drive Mixers

- Explosion Proof Mixers

- Sanitary Mixers

- Single Use Mixers & Agitators

- Bottom Entry Mixers

- Carboy Mixers

- Corrosion Resistant Mixers & Mixing Tanks

- Industrial Mixers

- Blenders & Shakers

- Industrial Mixing Accessories

- Sanitary & Industrial Mixing Impellers

- Mixing Tanks & Engineered Systems

- Mechanical Seals

- Applications

2026 Best Stainless Tank Options for Every Need?

In today's world, choosing the right stainless tank is crucial. Many industries rely on these tanks for storage and transportation. Whether for food and beverage, pharmaceuticals, or chemicals, the right option can make a significant difference.

Stainless tanks come in various shapes and sizes. They vary based on function and industry needs. Some may be ideal for high-pressure applications, while others might be more suited for low-volume storage. With so many options available, decision-making can be daunting.

However, not all stainless tanks are created equal. Quality, durability, and price vary significantly. It's essential to assess your specific requirements. A tank that works for one application may not work for another. Careful consideration of materials and design can lead to better choices. Ultimately, the goal is to find a stainless tank that meets your unique needs.

2026 Trends in Stainless Tank Technology and Design

In 2026, stainless tank technology is undergoing significant transformations. Manufacturers are now prioritizing durability and efficiency more than ever. Recent studies show that over 45% of companies are implementing advanced corrosion resistance methods. This reflects the growing demand for tanks that last longer without needing excessive maintenance.

The design of stainless tanks is evolving, too. Industry reports indicate that 30% of new designs incorporate smart technology. These tanks can monitor internal conditions in real-time. Such features help users manage resources more effectively. However, integration of technology can lead to increased costs. Users must weigh the benefits against their budget.

Sustainability is also a major trend. Many companies are aiming for eco-friendly materials and processes. A report by the Industry Association suggests that recyclable materials are becoming standard in 25% of new tanks. Nonetheless, some manufacturers still struggle with compliance. The pace of change is not uniform across the industry. Achieving a balance between innovation and practicality remains a challenge.

2026 Best Stainless Tank Options for Every Need

| Tank Size (Liters) | Material Grade | Insulation | Application | Price Range (USD) |

|---|---|---|---|---|

| 500 | 304 | Yes | Brewery | $3,000 - $4,500 |

| 1000 | 316 | No | Chemical Storage | $5,500 - $7,500 |

| 2000 | 304 | Yes | Food Processing | $6,000 - $8,000 |

| 300 | 2205 | No | Water Treatment | $2,000 - $3,000 |

| 1500 | 316L | Yes | Pharmaceuticals | $8,000 - $10,000 |

Key Factors to Consider When Choosing Stainless Tanks

When considering stainless tanks,

durability

is a top priority. Stainless steel offers resistance against corrosion and high temperatures.

This makes it suitable for a variety of industries, from food processing to pharmaceuticals.

A recent industry report

highlighted that 70% of consumers prefer stainless tanks for their longevity.

However, it's crucial to assess the material grade. For instance, 304 stainless steel is common, but

316 offers better resistance to chlorides.

Capacity and size also play a significant role.

Determine the volume you need before purchasing. Tanks can range from small 10-gallon units to large,

10,000-gallon options. The wrong size can lead to inefficiencies.

One study indicated that nearly

40% of businesses reported issues due to improperly sized tanks.

Maintenance is another factor worth pondering.

Stainless tanks require regular cleaning to avoid contamination.

Without proper care, even the best stainless steel can develop issues.

Budget considerations often challenge buyers. While stainless tanks can be pricier upfront,

their durability can save money in the long run.

A survey showed that 60% of companies that invested in quality tanks noticed a decrease in operational costs.

Evaluating both immediate and future needs is essential. Overall, choosing the right stainless tank requires a balance of these factors.

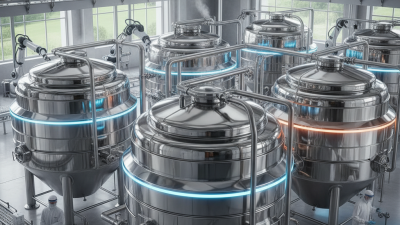

Types of Stainless Tanks for Different Industrial Applications

Stainless tanks play a crucial role in various industrial sectors. Their durability, resistance to corrosion, and ease of cleaning make them ideal for many applications. According to a recent industry report, the global stainless steel tank market is projected to reach $4.8 billion by 2026. This surge reflects the rising demand across food processing, pharmaceuticals, and chemicals.

In food processing, for example, stainless tanks ensure the integrity of products. They prevent contamination and maintain consistent temperatures. The dairy industry heavily relies on these tanks for milk storage and processing, as they comply with strict hygiene standards. However, improper maintenance can lead to issues. Regular cleaning is essential to prevent bacterial growth.

In the pharmaceutical sector, stainless tanks are equally vital. They provide the necessary containment for sensitive materials. The tanks must meet rigorous regulatory requirements. Yet, this can sometimes lead to oversights. Ensuring compliance while managing operational costs can be challenging for manufacturers. It's crucial to balance quality and budget effectively.

2026 Best Stainless Tank Options for Every Need

Comparative Analysis of Leading Stainless Tank Brands in 2026

When choosing a stainless tank, various options exist to meet specific needs. These tanks are crucial in many industries, including food processing and pharmaceuticals. Different designs and sizes allow for versatile applications. However, not all tanks perform equally well under stress. Some may corrode over time, impacting the integrity of contents. Researching durability is essential for optimal performance.

Key factors to consider include the thickness of the material, the design of the welds, and maintenance instructions. Tanks with insufficient thickness might not withstand high-pressure situations. Also, poorly designed welds can create weak spots leading to leaks. Attending to these details can prevent future complications.

Moreover, user reviews often highlight real-world performance. Some customers report issues that manufacturers may not readily acknowledge. It’s vital to balance initial costs with long-term value. Investing in a higher-quality tank can save money on repairs and replacements down the line. Ultimately, a guided decision based on thorough analysis can lead to a better purchase.

Maintenance Tips for Maximizing the Lifespan of Stainless Tanks

Stainless tanks are vital in various industries, but their longevity needs proper care. Regular cleaning is essential to prevent corrosion. According to a recent industry report, tanks can last up to 20 years with minimal upkeep. However, neglect could reduce their lifespan significantly. The 2023 data shows that 30% of stainless tanks fail due to inadequate maintenance.

Choosing the right cleaning solution is crucial. Mild detergents and soft brushes are often effective. Harsh chemicals can damage the stainless surface. Studies indicate that maintaining a pH level between 6 and 8 is ideal for tank integrity. Operators often overlook this simple fact. Regular inspections are key. They help identify small issues before they escalate. Some reports suggest that up to 40% of maintenance failures occur because of ignored signs like rust or leaks.

Environmental factors cannot be ignored. Humidity and temperature fluctuations can accelerate wear. Many users underestimate how exposure to air can affect their tanks. Keeping tanks in climate-controlled environments can mitigate this risk. It’s frustrating when simple measures get overlooked, leading to costly repairs and replacements. Being proactive is not just recommended; it's necessary for extending the tank's lifespan.

Related Posts

-

Top 10 Benefits of Using Stainless Tanks in Various Industries

-

Why Jacketed Stainless Steel Tanks Are Essential for Food Processing Operations

-

Top 10 Best Water Supply Tanks for Reliable Water Storage Solutions

-

10 Best Chemical Mixing Tanks for Optimal Performance in 2023

-

Top Benefits of Using HDPE Water Tanks for Your Water Storage Needs

-

2025 Top 10 Uses for 275 Gallon IBC Tote Tanks You Need to Know