- Blenders, Mixers, & Agitators

- Tri Clamp Mixers

- Top Entry Mixers

- High Viscosity Mixers

- Mag Drive Mixers

- Explosion Proof Mixers

- Sanitary Mixers

- Single Use Mixers & Agitators

- Bottom Entry Mixers

- Carboy Mixers

- Corrosion Resistant Mixers & Mixing Tanks

- Industrial Mixers

- Blenders & Shakers

- Industrial Mixing Accessories

- Sanitary & Industrial Mixing Impellers

- Mixing Tanks & Engineered Systems

- Mechanical Seals

- Applications

How to Choose the Right IBC Storage Tank for Your Needs

When it comes to managing liquids in various industries, the selection of an appropriate storage solution is paramount. One such option that has gained significant traction is the IBC storage tank (Intermediate Bulk Container), known for its versatility and efficiency. According to a report by the Global IBC Container Market, the demand for IBC storage tanks is projected to grow at a CAGR of 4.5% between 2021 and 2026, driven by the rise in bulk transport needs across sectors such as chemicals, pharmaceuticals, and food. The unique design of IBC tanks allows for easy transportation and storage of liquids, accommodating a wide range of materials in a safe and secure manner.

Choosing the right IBC storage tank for your needs involves understanding various factors including material compatibility, size, and regulatory compliance. The correct choice can dramatically enhance operational efficiency, reduce costs, and ensure product integrity. Industry experts estimate that improper tank selection can lead to losses upwards of 20%, emphasizing the importance of conducting thorough research and analysis before making a purchase. This article aims to guide you through the critical aspects of selecting the ideal IBC storage tank tailored to your specific applications, ensuring both safety and compliance in your operations.

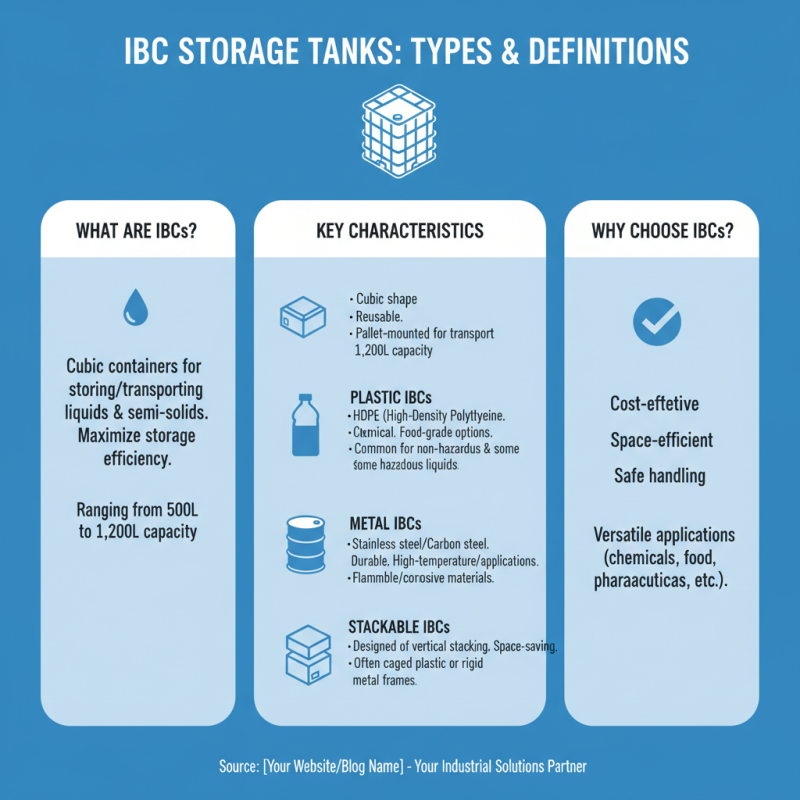

Understanding IBC Storage Tanks: Definitions and Types

Intermediate Bulk Containers (IBCs) are essential for storing and transporting a wide range of liquids and semi-solids. They typically come in a cubic shape and are designed to maximize storage efficiency. Understanding the types and definitions of IBC storage tanks is crucial for selecting the right one for specific applications. Generally, IBCs are categorized into several types, including plastic, metal, and stackable containers, each tailored to different materials and environments.

Plastic IBCs are commonly used for chemical and food-grade liquids due to their corrosion-resistant properties. They offer a lightweight solution that makes handling and transportation more straightforward. Metal IBCs, on the other hand, are ideal for more hazardous materials as they provide enhanced durability and safety. Stackable IBCs are designed to optimize space and can be stacked securely, providing an effective storage solution for facilities with limited room. Understanding these variations is imperative, as it allows businesses to choose the correct IBC that meets their specific storage needs while ensuring compliance with safety regulations and operational efficiency.

Key Factors to Consider When Selecting an IBC Storage Tank

When selecting the right Intermediate Bulk Container (IBC) storage tank, several key factors must be taken into account to ensure optimal functionality and safety. First and foremost, it's essential to consider the compatibility of the tank materials with the substances being stored. According to a report by the International Container Management Association (ICMA), around 25% of chemical spills are a result of inadequate material selection. Therefore, choosing tanks made from high-density polyethylene (HDPE) or stainless steel can enhance performance and reduce the risk of chemical reactions that may lead to spills.

Another crucial factor is the tank's capacity and design. IBC tanks typically range from 275 to 330 gallons, making it vital to assess your storage needs accurately. A comprehensive study by the Global IBC Market Research indicates that improper sizing accounts for over 15% of inefficiencies in logistics and storage processes within warehouses. Additionally, consider the tank's accessibility and placement, as it should facilitate easy filling and dispensing while adhering to local regulations regarding safety and environmental impact.

Lastly, focus on additional features such as stackability and portability. As noted in the Warehousing and Logistics Capacity Report, IBC tanks that are stackable can save up to 25% more space, making them a practical choice for businesses looking to optimize storage costs. Evaluating these key factors will not only guarantee the selection of the most suitable IBC storage tank but also contribute to the efficiency and safety of storage operations.

IBC Storage Tank Selection Factors

Assessing Compatibility: Material and Chemical Properties

When selecting an Intermediate Bulk Container (IBC) storage tank, the compatibility between the tank's material and the chemical properties of the contents is crucial. Different chemicals can react differently with various materials, which can lead to issues such as degradation of the tank, leaks, or even hazardous reactions. For instance, polyethylene tanks are excellent for a wide range of chemicals; however, they may not be suitable for aromatic hydrocarbons or certain solvents. Assessing the chemical’s compatibility can help prevent accidents and preserve the integrity of the tank.

Moreover, it's important to consider environmental factors and the specific storage conditions. For chemicals that are sensitive to temperature fluctuations or environmental exposure, selecting a tank with appropriate insulation or UV protection can extend the life of the storage system. Conducting thorough research into both the chemical nature and the physical properties of the tank material will ensure that the chosen IBC can withstand potential stressors. By carefully evaluating these factors, users can make informed decisions that enhance safety and efficiency in their operations.

Determining Size and Capacity Requirements for Your Applications

When selecting the right Intermediate Bulk Container (IBC) storage tank for your needs, determining the size and capacity requirements is crucial. First, assess the volume of material you plan to store. Understanding the total quantity and the nature of the substance will help you decide on the appropriate tank size. For example, if you regularly deal with large quantities of liquids, opting for larger capacity tanks may prove more efficient, reducing the number of refills and maximizing storage space.

Additionally, consider the physical dimensions of the space where the IBC tank will be placed. It is important to ensure that the tank fits comfortably in your designated storage area while allowing for safe access and ventilation. Always account for additional space needed for handling equipment, as well as any regulatory requirements governing the positioning of storage tanks. By carefully gauging both your capacity needs and the available space, you can make an informed decision that enhances operational efficiency and safety in your facility.

Best Practices for Maintaining and Managing IBC Storage Tanks

When it comes to maintaining and managing IBC (Intermediate Bulk Container) storage tanks, implementing best practices is essential for ensuring safety, efficiency, and longevity. Regular inspections should form the backbone of any maintenance regime; check for signs of wear, leaks, or damage, as these issues can compromise both the integrity of the tank and the safety of the stored materials. Keeping a detailed log of inspections and maintenance activities can help identify patterns over time, indicating when specific tanks may need more frequent attention.

In addition to regular inspections, proper cleaning and sanitization of IBC tanks are vital. Depending on the materials stored, residue can build up and affect the quality of the contents, particularly in food-grade applications. Establishing a routine cleaning schedule, using appropriate cleaning agents compatible with the stored material, will help keep tanks in optimal condition. It is equally important to ensure that tanks are stored in a controlled environment, shielded from extreme temperatures and direct sunlight, which can degrade materials over time. By adhering to these best practices, you can enhance the performance and lifespan of your IBC storage tanks.