- Blenders, Mixers, & Agitators

- Tri Clamp Mixers

- Top Entry Mixers

- High Viscosity Mixers

- Mag Drive Mixers

- Explosion Proof Mixers

- Sanitary Mixers

- Single Use Mixers & Agitators

- Bottom Entry Mixers

- Carboy Mixers

- Corrosion Resistant Mixers & Mixing Tanks

- Industrial Mixers

- Blenders & Shakers

- Industrial Mixing Accessories

- Sanitary & Industrial Mixing Impellers

- Mixing Tanks & Engineered Systems

- Mechanical Seals

- Applications

How to Choose the Right Stainless Tank for Your Needs and Applications

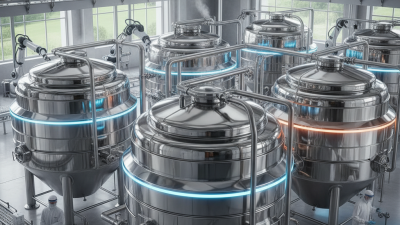

When it comes to selecting the right stainless tank, understanding the unique demands of your industry is crucial. According to renowned stainless tank industry expert Dr. Emily Foster, "Choosing the correct stainless tank is not just about durability; it's about ensuring that the tank's specifications match the operational requirements of your applications." This sentiment underscores the importance of thoughtful consideration when making your selection.

Stainless tanks serve a variety of functions across many sectors, from food and beverage processing to pharmaceuticals and chemical manufacturing. Each application may require different features, such as size, shape, and resistance to corrosion. As such, it becomes essential to assess the specific needs of your processes before making a decision. This guide will help you navigate the complexities of selecting a stainless tank that not only meets regulatory standards but also enhances operational efficiency.

By understanding the critical elements involved in choosing a stainless tank, you can make informed decisions that support your business objectives. Whether you are an experienced professional or a newcomer to the industry, grasping the nuances of stainless tanks will empower you to select the best solutions for your applications and contribute to your overall success.

Understanding the Different Types of Stainless Tanks

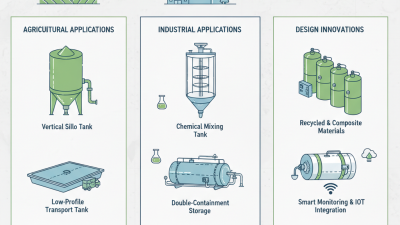

When selecting the right stainless tank for your needs, it's essential to understand the various types available. Stainless tanks are primarily categorized based on their construction and intended use. For instance, you might encounter horizontal or vertical tanks, each designed for specific application requirements. Horizontal tanks are often used when space is limited, while vertical tanks can offer a larger storage capacity within a smaller footprint.

Another crucial distinction among stainless tanks is the grade of stainless steel used in their construction. Grades like 304 and 316 are common, with 316 being more resistant to corrosion and suitable for chemical or marine applications. This decision directly impacts the tank’s longevity and performance under different environmental conditions.

Tips: When choosing a tank, always consider the nature of the substances you will store and how they might interact with the tank material. Additionally, it's wise to assess the maintenance requirements of the different tank types. Regular inspections and cleaning can prolong the lifespan of your stainless tank, ensuring it performs effectively for years to come.

Key Factors to Consider When Selecting a Stainless Tank

When selecting the right stainless tank for your needs and applications, several key factors should be taken into account to ensure optimal performance and longevity. One of the primary considerations is the tank's material grade; typically, 304 and 316 stainless steels are the most commonly used. According to industry reports, 316-grade stainless steel is often preferred for corrosive environments due to its higher resistance to chlorides. This can significantly extend the lifespan of the tank, making it essential for applications like chemical storage and food processing, where hygiene and corrosion resistance are crucial.

Another important factor is the tank's capacity and dimensions, as these will directly impact its functionality in your specific application. For instance, a report from the Metal Tank Manufacturers Association indicates that dimensions that align with industry-standard sizes can facilitate easier transport and integration into existing systems. Additionally, consider the intended use of the tank—whether it requires insulation for temperature control or specific fittings for loading and unloading. These requirements can greatly influence the design and construction of the tank, ensuring that it meets the demands of your operations efficiently and safely.

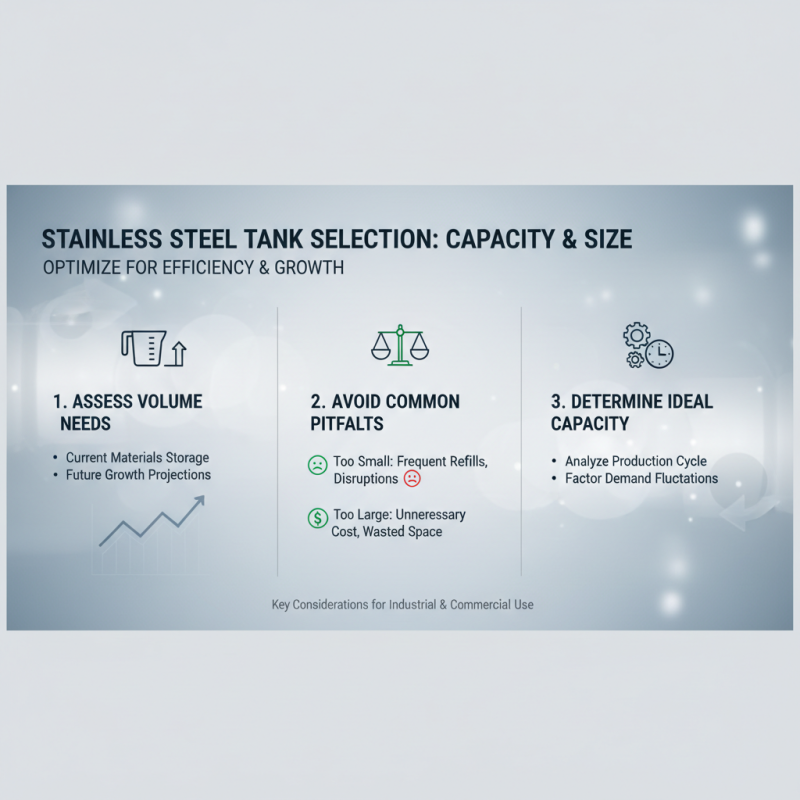

Evaluating the Capacity and Size Requirements for Your Application

When selecting a stainless tank for your specific application, evaluating the capacity and size requirements is crucial. Start by identifying the volume of materials you need to store or process. This involves considering both current needs and future growth. If the tank is too small, you risk frequent refills and disruptions in operations. Conversely, an oversized tank can lead to unnecessary costs and wasted space. Analyze your production cycle to determine how much capacity is ideal, keeping in mind any fluctuations in demand.

In addition to capacity, the physical dimensions of the tank should align with your available space and installation requirements. Measure the area where the tank will be positioned, accounting for any access needed for maintenance and operation. Height, width, and overall footprint are vital considerations. Ensure the design of the tank fits seamlessly within your facility's layout while also adhering to safety regulations. By carefully evaluating these parameters, you can make a well-informed decision that enhances the efficiency and effectiveness of your operations.

Material Grades and Specifications of Stainless Steel for Tanks

When selecting a stainless steel tank, understanding the material grades and specifications of stainless steel is crucial to ensuring that the tank meets your specific needs and applications. Stainless steel is not a single material; instead, it comprises various grades, each with unique properties that influence its performance under different conditions. For instance, the most commonly used grades for tank construction include 304 and 316 stainless steels. Grade 304, known for its good corrosion resistance and formability, is often utilized in food and beverage applications, while grade 316, which contains molybdenum, offers enhanced resistance to chloride corrosion, making it more suitable for environments exposed to salty or acidic substances.

When assessing the specifications of stainless steel tanks, one must also consider factors such as thickness, finish, and capacity. The thickness of the material impacts the tank’s durability and ability to withstand internal pressure, while the surface finish can affect hygiene and cleaning protocols, especially in industries like pharmaceuticals and food processing. Additionally, the tank's capacity should align with your production or storage requirements, as oversized or undersized tanks can lead to inefficiencies. By carefully evaluating the material grades and specifications, you can make an informed decision that enhances both the functionality and longevity of your stainless steel tank.

How to Choose the Right Stainless Tank for Your Needs and Applications

| Material Grade | Common Applications | Corrosion Resistance | Strength Properties | Temperature Resistance |

|---|---|---|---|---|

| 304 | Food processing, Dairy, Brewery | Good | Moderate | Up to 870°C |

| 316 | Marine environments, Chemical processing | Excellent | Moderate | Up to 870°C |

| 321 | High temperature applications, Aerospace | Good | High | Up to 900°C |

| 430 | Kitchen utensils, Automotive applications | Fair | Moderate | Up to 815°C |

| Duplex 2205 | Oil and gas, Marine applications | Excellent | High | Up to 600°C |

Maintenance and Durability Considerations for Stainless Tanks

When choosing a stainless steel tank, it's essential to consider maintenance and durability to ensure long-term functionality and safety. Regular maintenance is vital for preserving the tank's integrity; this includes routine inspections for corrosion or damage, especially in areas subjected to moisture or chemicals. Cleaning the tank periodically with appropriate methods is also crucial to prevent buildup of contaminants that can affect the quality of stored materials.

Durability is one of the main advantages of stainless steel tanks, as they are resistant to rust and corrosion. However, factors such as temperature fluctuations, exposure to harsh chemicals, and physical impact can affect their lifespan. Selecting a high-quality stainless steel grade tailored to your specific application—such as food storage, chemical processing, or water treatment—can enhance durability. Additionally, investing in protective coatings or linings can further extend the tank's life by providing an additional barrier against environmental factors. Proper handling and installation practices also play a significant role in minimizing wear and tear, ensuring that the tank meets your operational needs efficiently.

Related Posts

-

How to Choose the Right IBC Storage Tank for Your Needs

-

Top 10 Best Water Supply Tanks for Reliable Water Storage Solutions

-

Why Jacketed Stainless Steel Tanks Are Essential for Food Processing Operations

-

2025 Top PE Tank Designs: What You Need to Know for Your Projects

-

Top 5 Benefits of Using PE Tanks for Water Storage Solutions

-

10 Best Chemical Mixing Tanks for Optimal Performance in 2023